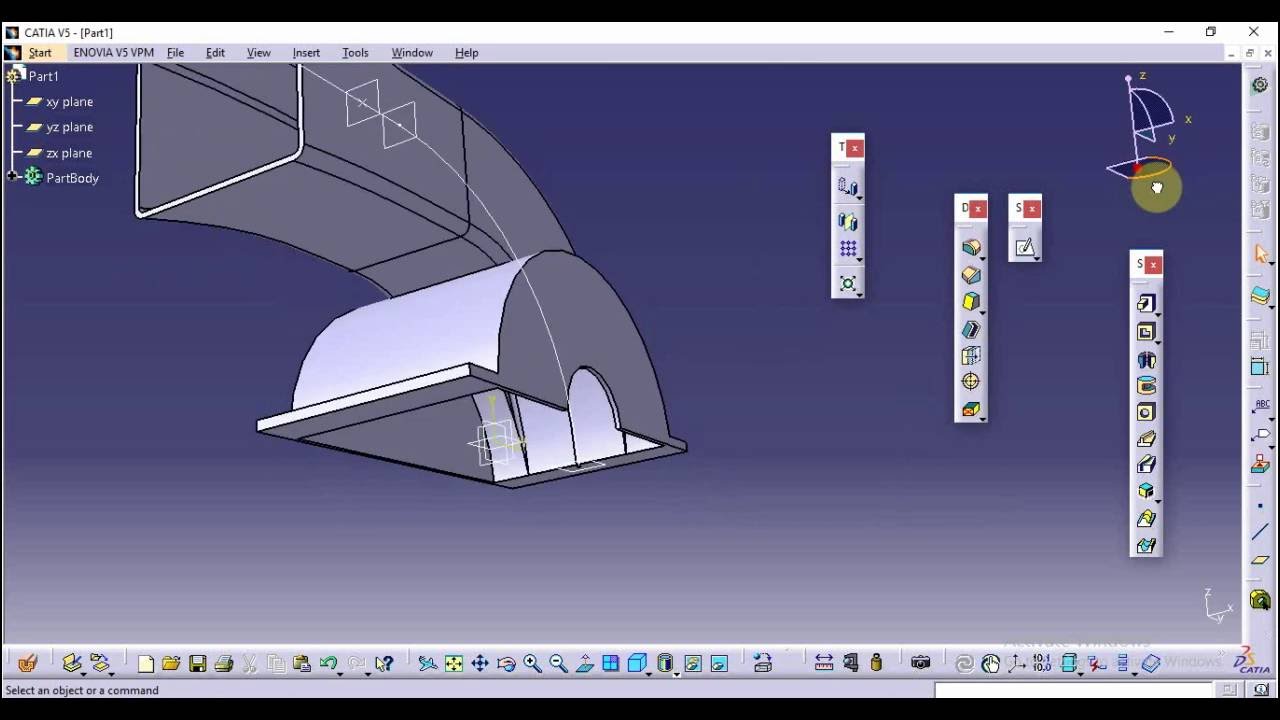

Blower Impeller Design Software

Service Provider of Software Package - Fan Design Software, Bag Filters Design Software, Screw Conveyor Design Software and Centrifugal Fans And Blowers. This software covers all types of Fan like ID,FD,SA etc. An ideal range of static pressure(10mm to1200mmWG.

A typical backward-curved centrifugal fan, where the blades curve away from the direction they rotate. A centrifugal fan is a mechanical device for moving or other. The terms 'blower' and 'squirrel cage fan', (because it looks like a ), are frequently used as synonyms. These fans increase the speed and volume of an air stream with the rotating. Centrifugal fans use the kinetic energy of the to increase the volume of the air stream, which in turn moves them against the resistance caused by ducts, dampers and other components. Centrifugal fans displace air radially, changing the direction (typically by 90°) of the airflow.

They are sturdy, quiet, reliable, and capable of operating over a wide range of conditions. Centrifugal fans are constant displacement devices or constant volume devices, meaning that, at a constant fan speed, a centrifugal fan moves a relatively constant volume of air rather than a constant mass. This means that the air velocity in a system is fixed even though the mass flow rate through the fan is not. [ ] Centrifugal fans are not positive displacement devices.

Centrifugal fans have certain advantages and disadvantages when contrasted with positive-displacement blowers. The centrifugal fan is one of the most widely used fans. Centrifugal fans are by far the most prevalent type of fan used in the industry today. They are often cheaper than axial fans and simpler in construction. They are used in transporting gas or materials and in ventilation systems for buildings and vehicles.

They are also well-suited for processes and control systems. The centrifugal fan is a drum shape composed of a number of fan blades mounted around a hub.

As shown in the animated figure, the hub turns on a mounted in bearings in the fan housing. The gas enters from the side of the fan, turns 90 degrees and due to as it flows over the fan blades and exits the fan housing. Contents • • • • • • • • • • • • • • • • • • • • • • • • History [ ] The earliest mention of centrifugal fans was in 1556 by Georg Pawer (Latin: ) in his book, where he shows how such fans were used to ventilate mines. Timeline Template Omni Graffle Stencils. Thereafter, centrifugal fans gradually fell into disuse. It wasn't until the early decades of the nineteenth century that interest in centrifugal fans revived. In 1815 the Marquis de Chabannes advocated the use of a centrifugal fan and took out a British patent in the same year.

In 1827, Edwin A. Stevens of Bordentown, New Jersey, installed a fan for blowing air into the boilers of the steamship North America. Similarly, in 1832, the Swedish-American engineer used a centrifugal fan as blower on the steamship Corsair. A centrifugal fan was invented by Russian military engineer in 1832, and was used both in the Russian light industry (such as sugar making) and abroad. One of the most important developments for the mining industry was the, which was patented in in 1862 by the French engineer.

The Guibal fan had a spiral case surrounding the fan blades, as well as a flexible shutter to control the escape velocity, which made it far superior to previous open-fan designs and led to the possibility of mining at great depths. Such fans were used extensively for mine ventilation throughout Britain. Construction [ ]. Forward-curved blades in a household fan Forward-curved blades, as in Figure 3(a), curve in the direction of the fan wheel's rotation. These are especially sensitive to particulates. Rons Cyborg Parts RARE.

[ ] Forward-curved blades provide a low noise level and relatively small air flow with a high increase in static pressure. Backward-curved [ ] Backward-curved blades, as in Figure 3(b), curve against the direction of the fan wheel's rotation. Smaller blowers may have backward-inclined blades, which are straight, not curved. Larger backward-inclined/-curved blowers have blades whose backward curvatures mimic that of an airfoil cross section, but both designs provide good operating efficiency with relatively economical construction techniques. These types of blowers are designed to handle gas streams with low to moderate particulate loadings [ ].

They can be easily fitted with wear protection but certain blade curvatures can be prone to solids build-up. Backward curved wheels are often heavier than corresponding forward-curved equivalents, as they run at higher speeds and require stronger construction. Backward curved fans can have a high range of specific speeds but are most often used for medium specific speed applications—high pressure, medium flow applications. [ ] Backward-curved fans are much more energy efficient than radial blade fans and so, for high power applications may be a suitable alternative to the lower cost radial bladed fan. [ ] Straight radial [ ] Radial blowers, as in Figure 3(c), have wheels whose blades extend straight out from the centre of the hub. Radial bladed wheels are often used on particulate-laden gas streams because they are the least sensitive to solid build-up on the blades, but they are often characterized by greater noise output.

High speeds, low volumes, and high pressures are common with radial blowers [ ], and are often used in, pneumatic material conveying systems, and similar processes. Principles of operation [ ] The centrifugal fan uses the centrifugal power supplied from the rotation of impellers to increase the kinetic energy of air/gases. When the impellers rotate, the gas particles near the impellers are thrown-off from the impellers, then moves into the fan casing.

As a result, the kinetic energy of gas is measured as pressure because of the system resistance offered by the casing and duct. The gas is then guided to the exit via outlet ducts. After the gas is thrown-off, the gas pressure in the middle region of the impellers decreases. The gas from the impeller eye rushes in to normalize this. This cycle repeats and therefore the gas can be continuously transferred. Table 1 Differences between fans and blowers Equipment Pressure Ratio Pressure rise (mm H2O) Fans Up to 1.1 1136 Blowers 1.1 to 1.2 1136-2066 Velocity triangle [ ].

Main article: A diagram called a velocity triangle helps us in determining the flow geometry at the entry and exit of a blade. A minimum number of data are required to draw a velocity triangle at a point on blade.

Some component of velocity varies at different point on the blade due to changes in the direction of flow. Hence an infinite number of velocity triangles are possible for a given blade. To describe the flow using only two velocity triangles, we define mean values of velocity and their direction. Velocity triangle of any turbo machine has three components as shown. Velocity triangle for backward-facing blade Difference between fans and blowers [ ] The property that distinguishes a centrifugal fan from a blower is the pressure ratio it can achieve.

In general, a blower can produce a higher pressure ratio. As per (ASME) the specific ratio - the ratio of the discharge pressure over the suction pressure – is used for defining the fans and blowers (Table 1).

[ ] Ratings [ ] Ratings found in centrifugal fan performance tables and curves are based on standard air. Fan manufacturers define standard air as clean, dry air with a of 0.075 pounds mass per cubic foot (1.2 kg/m³), with the at sea level of 29.92 inches of mercury (101.325 kPa) and a of 70 °F (21 °C). Selecting a centrifugal fan to operate at conditions other than standard air requires adjustment to both static pressure and. At higher-than-standard elevation () and higher-than-standard temperature, is lower than standard density. Air density corrections must accounted for centrifugal fans that are specified for continuous operation at higher temperatures. The centrifugal fan displaces a constant volume of air in a given system regardless of air density.

When a centrifugal fan is specified for a given CFM and static pressure at conditions other than standard, an air density correction factor must be applied to select the proper size fan to meet the new condition. Since 200 °F (93 °C) air weighs only 80% of 70 °F (21 °C) air, the centrifugal fan creates less pressure and requires less power. To get the actual pressure required at 200 °F (93 °C), the designer must multiply the pressure at standard conditions by an air density correction factor of 1.25 (i.e., 1.0/0.8) to get the system to operate correctly.

To get the actual power at 200 °F (93 °C), the designer must divide the power at standard conditions by the air density correction factor. Air Movement and Control Association (AMCA) [ ] The centrifugal fan performance tables provide the fan RPM and power requirements for the given CFM and static pressure at standard air density. When the centrifugal fan performance is not at standard conditions, the performance must be converted to standard conditions before entering the performance tables.

Centrifugal fans rated by the (AMCA) are tested in laboratories with test setups that simulate installations that are typical for that type of fan. Usually they are tested and rated as one of four standard installation types as designated in AMCA Standard 210. AMCA Standard 210 defines uniform methods for conducting laboratory tests on housed fans to determine airflow rate, pressure, power and efficiency, at a given speed of rotation. The purpose of AMCA Standard 210 is to define exact procedures and conditions of fan testing so that ratings provided by various manufacturers are on the same basis and may be compared. For this reason, fans must be rated in standardized SCFM. This section does not any. Unsourced material may be challenged and.

(April 2015) () Centrifugal fans suffer efficiency losses in both stationary and moving parts, increasing the energy input required for a given level of airflow performance. Impeller entry [ ] Flow at the intake and its turning from axial to radial direction causes losses at the intake.

Friction and cause impeller blade losses since there is change in. [ ] These impeller blade losses are also included in the category. Leakage [ ] Leakage of some air and disturbance in the main flow field is caused due to the clearance provided between the rotating periphery of the impeller and the casing at the entry. Impeller [ ] Passage friction and flow separation cause impeller losses that depend on relative velocity, rate of diffusion, and blade geometry.

Impeller dynamic balancing usually is done on a precision balancing machine, because all energy of vibrational imbalance is lost (for example, this can easily amount to 50% of air-flow loss in poorly-maintained home AC units). [ ] Diffuser and volute [ ] Friction and flow separation also causes losses in the. Further losses due to incidence occur if the device is working beyond its design conditions.

Flow from the impeller or diffuser expands in the, which has a larger cross section leading to the formation of, which in turn reduces pressure head. Friction and flow separation losses also occur due the volute passage.

Disc friction [ ] Viscous on the back surface of the impeller disc causes disc friction losses. See also [ ] Wikimedia Commons has media related to. • • • • • • References [ ]. • Electrical Energy Equipment: Fans and Blowers. • Lawrence Berkeley National Laboratory Washington, DC Resource Dynamics Corporation Vienna, VA. Retrieved 29 February 2012. CS1 maint: Multiple names: authors list () • United Nations Environment Programme..

Quote: 'The centrifugal blower and the positive displacement blower are two main types of blowers' •. • Juan Loera, P.E.. • Jim Brown.. Retrieved 29 February 2012. • Singh, O.P.; Rakesh Khilwani; T.

Sreenivasulu; M. Kannan (May 2011). International Journal of Advances in Engineering & Technology.

Retrieved 29 February 2012. • ^ January 24, 2010, at the. ( website page) • Georgius Agricola with Herbert Clark Hoover and Lou Henry Hoover, trans., De Re Metallica (New York, New York: Dover Publications, Inc., 1950), • • Walter B. Snow (November 1898) Cassier's Magazine, 15 (1): 48–59; see p. • (Editorial staff) (March 1919) Mechanical Engineering, 41: 260–261; see p.

• 2009-10-20 at the. (in Russian) •, p. 45. Archived from on 17 March 2012. Retrieved 29 February 2012. • Juan Loera, P.E.. Retrieved 17 December 2014. • • ANSI/AMCA Standard 210-99, 'Laboratory Methods Of Testing Fans for Aerodynamic Performance Rating'.

• 93 Downloads Abstract Centrifugal blowers are widely used turbomachines equipment in all kinds of modern and domestic life. Manufacturing of blowers seldom follow an optimum design solution for individual blower. Although centrifugal blowers are developed as highly efficient machines, design is still based on various empirical and semi empirical rules proposed by fan designers. There are different methodologies used to design the impeller and other components of blowers. The objective of present study is to study explicit design methodologies and tracing unified design to get better design point performance.

This unified design methodology is based more on fundamental concepts and minimum assumptions. Parametric study is also carried out for the effect of design parameters on pressure ratio and their interdependency in the design. The code is developed based on a unified design using C programming. Numerical analysis is carried out to check the flow parameters inside the blower.

Two blowers, one based on the present design and other on industrial design, are developed with a standard OEM blower manufacturing unit. A comparison of both designs is done based on experimental performance analysis as per IS standard.

The results suggest better efficiency and more flow rate for the same pressure head in case of the present design compared with industrial one.